Grinder pumps are an integral part of our modern plumbing systems, serving a specific yet crucial role in waste management. These pumps, primarily used in sewage systems, are engineered to handle the toughest of waste, breaking them down into a fine slurry for easy transportation and disposal.

A grinder pump essentially is a wastewater conveyance device. Powered by electricity, it grinds waste from water-using household appliances (like toilets, bathtubs, and showers) into a fine slurry. This slurry is then transported to the local sanitary sewer system or septic tank.

Grinder pumps come into play in regions where gravity-based sewer systems are not feasible. They ensure smooth transportation of waste, preventing blockages and system overloads, making them indispensable in areas with challenging terrains or low-lying regions.

Basic Mechanics

Core Components of a Grinder Pump

Grinder pumps, while sophisticated, are made up of three main components:

- Motor: Provides the power to drive the pump and the grinding mechanism.

- Cutting System: This system slices and grinds the waste into slurry.

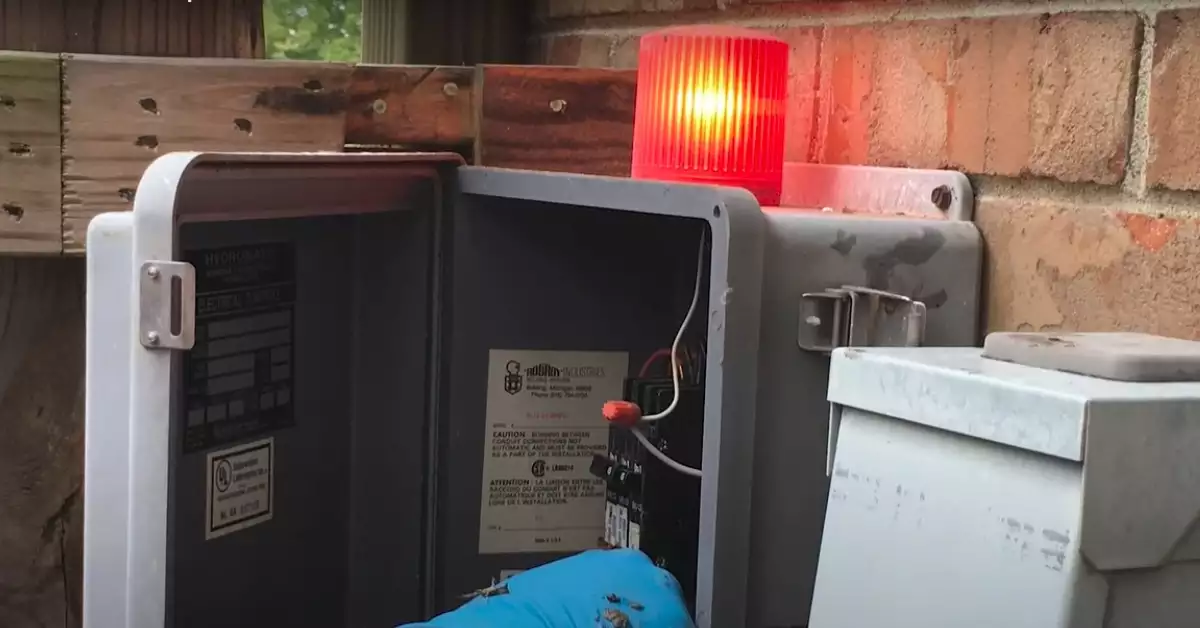

- Alarm System: Informs homeowners of any pump malfunctions.

How It Functions: A Step-by-Step Overview

- Wastewater flows into the tank of the grinder pump.

- Once the water reaches a certain level, the pump activates.

- The cutting system grinds the waste.

- The pump then pushes the slurry into the sewer system or septic tank.

Types of Grinder Pumps

Grinder pumps, with their essential role in the wastewater management process, come in various configurations, each tailored to specific requirements. While the primary function remains consistent, understanding the differences can help in making an informed decision.

Centrifugal vs. Positive Displacement

- Centrifugal Pumps:

- Mechanism: Uses centrifugal force generated by a spinning impeller to move water.

- Advantages: Generally less expensive and simpler in design.

- Drawbacks: Efficiency can decrease with increased pressure or when handling thicker slurry.

- Usage: Commonly found in residential settings where the demand is comparatively lower.

- Positive Displacement Pumps:

- Mechanism: Employs a rotating or reciprocating mechanism to displace a fixed volume of liquid with each cycle.

- Advantages: Can handle viscous fluids and maintain efficiency even at higher pressures.

- Drawbacks: Typically more complex and can be costlier than centrifugal pumps.

- Usage: Preferred in commercial or industrial setups where there’s a need to handle larger volumes or thicker slurry.

Standalone vs. Integrated Systems

- Standalone Pumps:

- Description: These are separate units from the holding tank, allowing for more flexibility in installation.

- Advantages: Easier to replace or service since only the pump can be detached without disturbing the tank.

- Drawbacks: Requires more space and sometimes more complicated plumbing setups.

- Integrated Systems:

- Description: Here, the pump and tank form a single cohesive unit.

- Advantages: Compact design makes it suitable for locations with space constraints. Additionally, integrated systems might have optimized flow dynamics due to their cohesive design.

- Drawbacks: If a component fails, the entire system might need servicing or replacement.

Residential vs. Commercial Applications

The distinction between residential and commercial grinder pumps lies primarily in their capacity, durability, and design complexities.

- Residential Grinder Pumps:

- Design: Tailored to handle waste from a single household or a few homes.

- Capacity: Typically designed to manage less volume compared to commercial pumps.

- Durability: While robust, residential pumps might not be designed for continuous operation.

- Commercial Grinder Pumps:

- Design: Built to handle waste from larger establishments like hotels, restaurants, or office buildings.

- Capacity: Can manage a significant volume of waste, often continuously.

- Durability: Made with heavy-duty materials to withstand the rigors of commercial usage.

Advantages of Using Grinder Pumps

Incorporating grinder pumps into wastewater management systems presents several notable advantages:

- Waste Reduction and Management:

- Efficiency: By grinding waste into slurry, grinder pumps ensure smoother flow in sewer lines, reducing the chances of blockages.

- Flexibility: The slurry can easily navigate through smaller diameter pipes, allowing for more flexible plumbing architectures.

- Efficient Use of Energy:

- Optimized Designs: Modern grinder pumps are designed keeping energy efficiency in mind, leading to reduced power consumption without compromising performance.

- Variable Speed Motors: Some advanced models can adjust their speed based on the load, further optimizing energy usage.

- Protection of Sewage Systems:

- Reduced Blockages: By breaking down large chunks of waste, grinder pumps significantly reduce the chances of blockages in the sewer system.

- Extended Lifespan: With fewer blockages, the overall stress on the sewage system decreases, potentially extending its lifespan.

- Cost Savings in Long-Term:

- Reduced Maintenance: Fewer blockages mean fewer callouts for maintenance.

- Longevity: A well-maintained grinder pump can save costs in the long run by serving efficiently for many years.

Common Issues and Solutions

Despite their efficiency, grinder pumps aren’t without their challenges. Addressing issues promptly ensures longevity and optimal function.

Clogging Concerns

- Causes:

- Introduction of non-degradable items like diapers, plastic, or even thick grease.

- Improper maintenance or irregular cleaning schedules.

- Prevention:

- Awareness campaigns or labels indicating what shouldn’t be introduced into the sewage system.

- Regular maintenance checks to ensure the cutting system remains sharp and effective.

Alarm System Failures

- Identifying:

- Regular monthly tests can ensure the alarm system is functional.

- Alarms are crucial as they alert homeowners to potential issues, preventing major malfunctions or overflows.

- Addressing:

- Most issues with alarm systems are related to power supply or sensor malfunctions. Regular inspections can preemptively identify and rectify these problems.

Wear and Tear Over Time

With constant use, some parts of the grinder pump will naturally wear out. Regular maintenance checks can help identify worn-out components, ensuring they are replaced promptly. Utilizing genuine parts and adhering to the manufacturer’s guidelines can ensure the pump continues to operate at its peak efficiency.

Selection and Installation

Factors to Consider Before Buying

When shopping for a grinder pump, consider:

- Size and Capacity: Suitable for your property and usage.

- Material and Durability: Corrosion-resistant materials are preferred.

- Brand and Warranty: Go for reputable brands with good warranty coverage.

Professional Installation vs. DIY

While DIY might seem tempting, professional installation ensures the grinder pump functions efficiently and safely.

Safety and Maintenance Tips

For a long-lasting grinder pump system:

- Regularly inspect and clean the system.

- Have a backup power source for outages.

- Note any unusual sounds or decrease in performance.

Environmental Impacts

Wastewater Treatment Advantages

Grinder pumps improve the efficiency of wastewater treatment by providing a consistent slurry that’s easier to process.

Potential Concerns and Remedies

Some older models may not be as energy-efficient. Upgrading to newer models or those with eco-friendly designs can mitigate environmental concerns.

Frequently Asked Questions

Why does my grinder pump keep running?

It could be due to a faulty switch or a malfunctioning component. Contact a professional to diagnose and fix the issue.

How long does a grinder pump last?

With proper care and maintenance, a grinder pump can last 8-15 years.

Can I install a grinder pump myself?

While possible, professional installation is recommended to ensure safety and efficiency.

Conclusion

Grinder pumps, though often overlooked, play a pivotal role in our wastewater management systems. Their ability to efficiently break down waste and transport it offers numerous advantages, both in terms of cost and environmental impact.

Moreover, while they do require attention and maintenance, the benefits they bring, from preventing sewer blockages to facilitating efficient wastewater treatment, far outweigh the occasional hitches.

Embracing advancements in grinder pump technology and adopting regular maintenance practices will ensure that these devices continue to serve our communities efficiently for years to come.